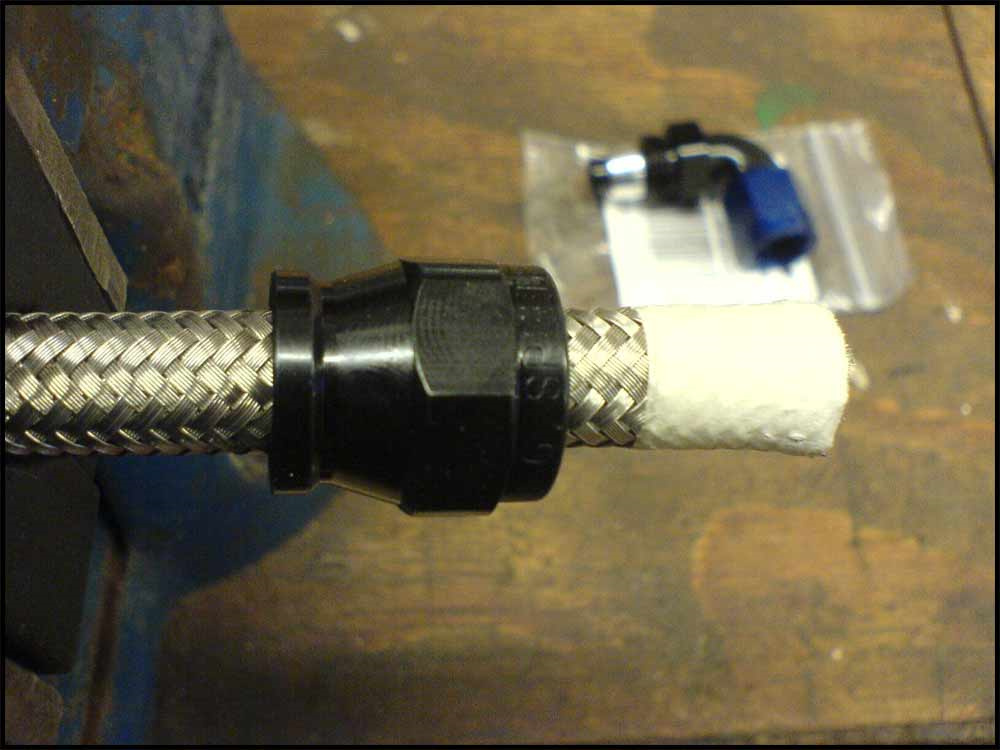

How To Install PTFE Hose Fittings – Step by Step Installation Guide This is a step by step guide that shows you precisely what to do. Follow these steps to have your PTFE hose fittings installed just like a Pro. Step 1 – Cutting PTFE Hose First we need to mark the cut position on the PTFE hose. To do this we wrap a piece of masking tape around the hose to cover the cut we are going to make. This serves two purposes, #1 to allow a pencil mark to be made in the exact position and #2 it will stop the stainless steel braid from flaring out as we cut. Most people assembling hoses at home will use a fine tooth metal saw to cut the hose, it’s the sort of tool you’ll already have. You could use hose shears or other commercial hose cutting equipment if you have access to it. Secure the hose before cutting in the plastic vice jaws. Cut square and let the saw blade do the cutting – do not force it. To install the PTFE hose fittings you will need to clean away any burrs from the PTFE tube. Any frayed stainless steel braids may be trimmed with snips. Step 2 We are now going to fit the PTFE hose fitting socket nut on to the PTFE hose. But first we should check the hose is round by gently squeezing with pliers. We also insert the PTFE hose fitting at this time as a check that the i.d. is round – remove it and put it to one side. Before removing the masking tape, slide the socket nut onto the PTFE hose. Be sure it’s the correct way around. Step 3 – Flaring The Braid Using a small screwdriver or pick, gentle expand the stainless steel braid away from the PTFE tube. Work all around the tube until done. Care should be taken to ensure the PTFE hose is not damaged. Step 4 – Installing the Olive / Ferrule Push the olive / ferrule onto the end of the PTFE tube and under the stainless steel braid. Ensure no braid lies between the tube and the olive / ferrule. This is important because it is not possible to install PTFE hose fittings and have a leak free seal if a piece of braid is caught beneath the olive. Complete the installation by pressing the end of the olive / ferrule against a flat surface. Inspect to ensure the PTFE tube butts up squarely and fully against the inside shoulder of the olive / ferrule. Step 5 Lubricate the threads on the socket nut, the hose end and also lubricate the PTFE hose fitting nipple using light oil. Insert the PTFE hose fitting into the PTFE hose by holding the hose and pushing the hose end nipple into the tube with a combined twisting pushing action. Check it is in as far as it will go. Step 6 Hold the socket nut in the vice jaws and, keeping the assembly square, start to engage the socket and PTFE hose fitting thread. It will be possible to start the threads by hand and to be sure the threads are correctly aligned. Step 7 Using the correct size spanner, tighten the PTFE hose fitting into the socket nut. Apply oil to the thread as you tighten up the union. Continue to tighten the PTFE hose fitting into the socket until you have a gap of approximately 1mm. Align the flats for a professional finish.

How To Install PTFE Hose Fittings – Step by Step Installation Guide This is a step by step guide that shows you precisely what to do. Follow these steps to have your PTFE hose fittings installed just like a Pro. Step 1 – Cutting PTFE Hose First we need to mark the cut position on the PTFE hose. To do this we wrap a piece of masking tape around the hose to cover the cut we are going to make. This serves two purposes, #1 to allow a pencil mark to be made in the exact position and #2 it will stop the stainless steel braid from flaring out as we cut. Most people assembling hoses at home will use a fine tooth metal saw to cut the hose, it’s the sort of tool you’ll already have. You could use hose shears or other commercial hose cutting equipment if you have access to it. Secure the hose before cutting in the plastic vice jaws. Cut square and let the saw blade do the cutting – do not force it. To install the PTFE hose fittings you will need to clean away any burrs from the PTFE tube. Any frayed stainless steel braids may be trimmed with snips. Step 2 We are now going to fit the PTFE hose fitting socket nut on to the PTFE hose. But first we should check the hose is round by gently squeezing with pliers. We also insert the PTFE hose fitting at this time as a check that the i.d. is round – remove it and put it to one side. Before removing the masking tape, slide the socket nut onto the PTFE hose. Be sure it’s the correct way around. Step 3 – Flaring The Braid Using a small screwdriver or pick, gentle expand the stainless steel braid away from the PTFE tube. Work all around the tube until done. Care should be taken to ensure the PTFE hose is not damaged. Step 4 – Installing the Olive / Ferrule Push the olive / ferrule onto the end of the PTFE tube and under the stainless steel braid. Ensure no braid lies between the tube and the olive / ferrule. This is important because it is not possible to install PTFE hose fittings and have a leak free seal if a piece of braid is caught beneath the olive. Complete the installation by pressing the end of the olive / ferrule against a flat surface. Inspect to ensure the PTFE tube butts up squarely and fully against the inside shoulder of the olive / ferrule. Step 5 Lubricate the threads on the socket nut, the hose end and also lubricate the PTFE hose fitting nipple using light oil. Insert the PTFE hose fitting into the PTFE hose by holding the hose and pushing the hose end nipple into the tube with a combined twisting pushing action. Check it is in as far as it will go. Step 6 Hold the socket nut in the vice jaws and, keeping the assembly square, start to engage the socket and PTFE hose fitting thread. It will be possible to start the threads by hand and to be sure the threads are correctly aligned. Step 7 Using the correct size spanner, tighten the PTFE hose fitting into the socket nut. Apply oil to the thread as you tighten up the union. Continue to tighten the PTFE hose fitting into the socket until you have a gap of approximately 1mm. Align the flats for a professional finish.